Process Competence TOX®-eClinching

Creation of conductivity

During TOX®-eClinching, a punch presses the sheets to be joined into a die. The undercut created by the plastic forming ensures high retention forces in the neck area. A material connection is also created, with excellent electrical conductivity.

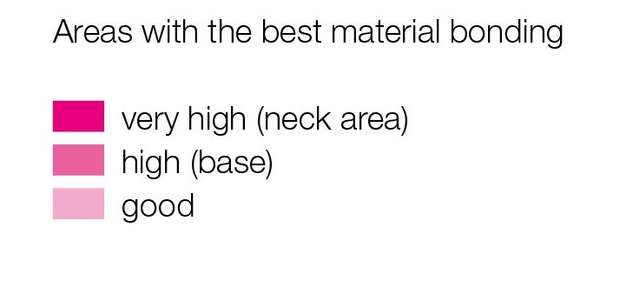

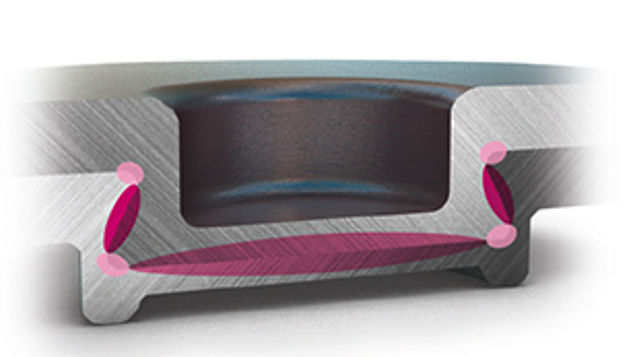

Joint zone with optimum material bonding

During the clinching process, in addition to the positive locking and frictional connection, there is also partial material bonding in the joint zone: The joined sheets flow into each other in such a way that an optimally conductive joint is created with the lowest possible contact resistance due to a large number of microcontacts.

Enlarged contact surface

The effective contact surface is almost doubled with the pulling-pressing process, it significantly increases with particularly great sheet metal thicknesses. This expanded surface additionally increases the conductivity of the joint.

Flowing coatings

Soft coatings, like for example tin coatings on copper, are also formed without pulling off, and thinned to a layer of just a few μm. Conductivity is maintained.

Numerous microcontacts ensure the conductive connection of the materials.

TOX®-eClinching is an efficient technology to join electrically conductive components safely and permanently, and equally mechanically and electrically.

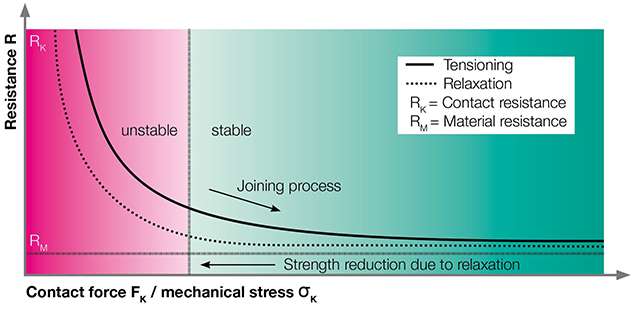

Constant conductivity with high retention forces

As clinch connections safely withstand mechanical stresses (e. g. torques) and temperature changes in the long-term, compared to other joining processes, relaxation processes – i. e. the relaxation of the connection – will only be minor. The contact resistance will therefore be constantly low, and the high conductivity will be maintained. This makes the procedure ideally suited to meet the high demands of the electrical industry.

Relaxations in the contact area

A TOX®-eClinch Point remains safely in the stable range (green area). The relaxations, which are principally unavoidable, are insignificant and practically not quantifiable. If the process-specific characteristics are not observed, there is a risk of entering the unstable range (red area).

Contact NZ: +49 751 50070 Contact form |

Cookie Information We use cookies to give you the best possible experience when using our website. You can block or regulate the use of cookies by adjusting your browser settings accordingly. |